¿48 minutes vs. 8 hours? the harsh reality of productivity in constructionRetryClaude can make mistakes. Please double-check responses'

If you work efficiently for just 48 minutes in the AEC sector (Architecture, Engineering, and Construction), you might be generating as much value as someone who spends a full 8-hour workday on the job — sadly, that’s not an exaggeration.

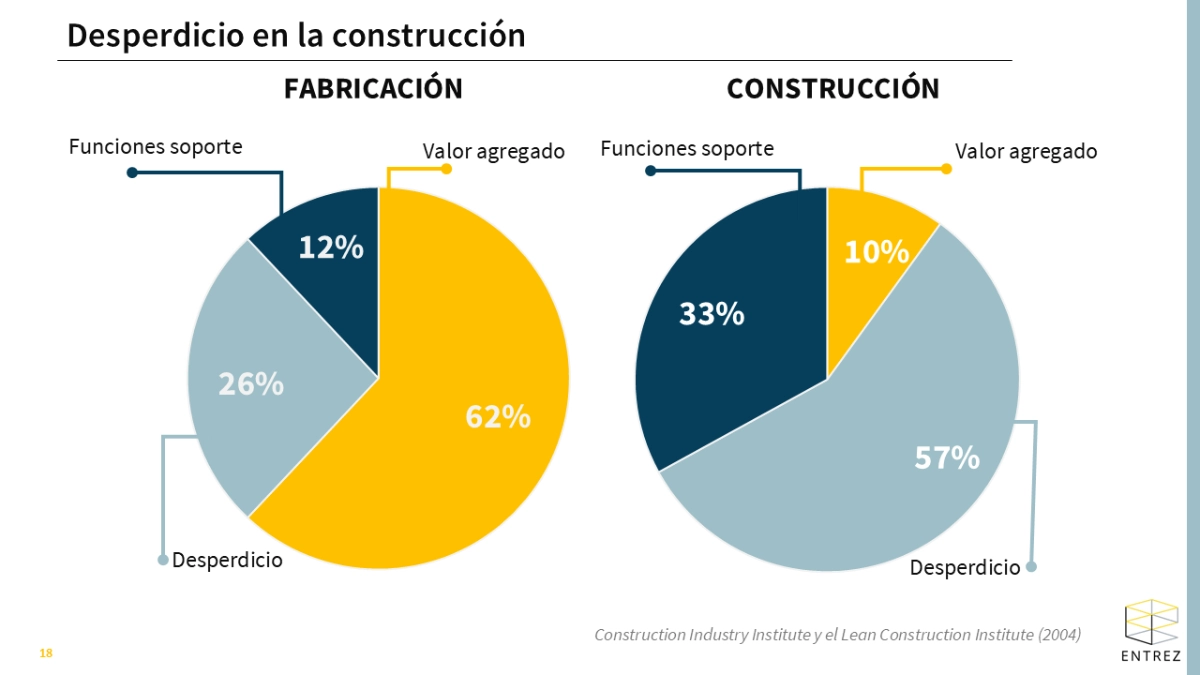

Let’s be honest. If you spend 4.5 hours of your workday checking social media, chatting with coworkers, and taking long coffee breaks, you may still be delivering the same level of productivity as someone attending endless meetings and “working” all day. In construction, 57% of the activities we perform are considered waste, according to the Lean Construction Institute (see Illustration 1).

Unlike industries such as manufacturing, oil & gas, or telecommunications, construction struggles with chronically low productivity. Our value streams are full of inefficiencies. Traditionally, we rely on the Transformation Model of production: input → transformation → output. But this model oversimplifies reality. It fails to consider the many variables that influence real project workflows, turning construction into a black box of assumptions.

This is where Koskela’s Transformation–Flow–Value (TFV) model becomes enlightening. It challenges us to rethink how we plan, control, and execute construction. It opens new doors to better practices and smarter workflows.

Two Root Causes Behind Our Productivity Gap Although productivity in construction is a deeply complex and well-studied issue, I want to highlight two key factors that, in my view, are especially critical:

- In architecture and engineering — particularly in engineering — we are trained to quickly define a problem and jump into solving it.

- If we don’t know the conditions of satisfaction for our deliverables, we are not truly working. We’re just going through the motions.

Let’s unpack both points.

The Rush to Solve Without Understanding We tend to leap into action without fully grasping the problem at hand — what Alejandro Gaviria calls "unthinking action". This leads us to design solutions that fail to address actual needs, whether explicit or latent. We end up creating inefficiencies and rework.

There's a deep-rooted pressure to appear busy. Many of us — and our managers — equate busyness with productivity. We chase optimization and continuous improvement because we believe our jobs depend on it.

Lean Thinking as a Low-Cost, High-Impact Solution A powerful way to identify waste in our workflows is Lean Thinking — a framework for doing more with less (Womack & Jones, 2000). Toyota’s historic example is instructive: during the post-WWII economic downturn and trade restrictions, they achieved outstanding global results by focusing relentlessly on value and eliminating waste.

Toyota identified seven types of waste, and Womack and Jones later added an eighth. We'll explore them in a future article, but their names are telling. Consider: how many of these forms of waste do you encounter during your own workday? And what about 100% on-site presence now, post-pandemic?

🛎️ (Para profundizar en las diferencias entre Eficacia y Eficiencia, recomiendo escuchar el fragmento del podcast de Atemporal y 13% con Mauricio Rodríguez, disponible en el siguiente enlace. Es una tarea que asigna a todos nuestros nuevos empleados. También lo escucho cada tanto.)

Respecto a la segunda arista, sobre las condiciones de satisfacción, quiero enfatizar lo siguiente: si trabajando para alguien más, necesitas preguntarle qué quiere, cuándo lo quieres, cómo lo quiere y cómo va a usar tu entregable. Si no tienes un cliente claro, DETENTE. No estás haciendo ningún trabajo real.

Si no conocemos claramente el requerimiento de nuestro jefe, colega o cliente, pasaremos de reproceso en reproceso, trabajando hasta tarde, llenos de estrés y ansiedad, sintiéndonos impostores y con relaciones laborales deterioradas. Estaríamos corriendo una maratón en la calle, pero encima de una caminadora.

¿Cuántas veces ha trabajado hasta tarde haciendo informes para que tu jefe los tenga a primera hora en su correo, solo para que los revise días después? ¿Cuántas veces te has esmerado en hacer un informe detallado cuando lo que se necesitaba era un resumen ejecutivo en formato de diapositiva? ¿Cuántas veces hemos iterado sobre diseños solo para descubrir que el presupuesto excede el máximo disponible por el cliente y hemos tenido que recortar el alcance luego de meses de trabajo? ¿Cuántas veces no ha creado planos de detalle y modelos LOD 350, para descubrir que no era lo que el cliente quería?

Just because we’re in front of a computer, attending Teams meetings, or creating deliverables doesn’t mean we’re generating real value. We must work harder to define what value truly means — before we begin any task. Only by clarifying value can we eliminate waste, our greatest enemy in the workplace. Perhaps then we can spend 60% of our day on high-impact activities — and reclaim more time for our lives beyond work.